For an episode of “Beyond the Concept” podcast, a show by Concept Systems, host Tyler Kern chatted with John Miller, the principal engineer at Rockwell Automations, and Jerry Flynn, the company’s principal controls engineer. The trio particularly discussed Programmable Numerical Control, mostly known by its initials, PNC, and how Rockwell has been a premier leader in the shift from computer numerical control, CNC, to programmable logic controller, or PLC. As Miller explained, PNC is a combination of both PLC and CNC. As its developer, he said he designed it over two decades ago because it was a necessary update in advancement to traditional CNC.

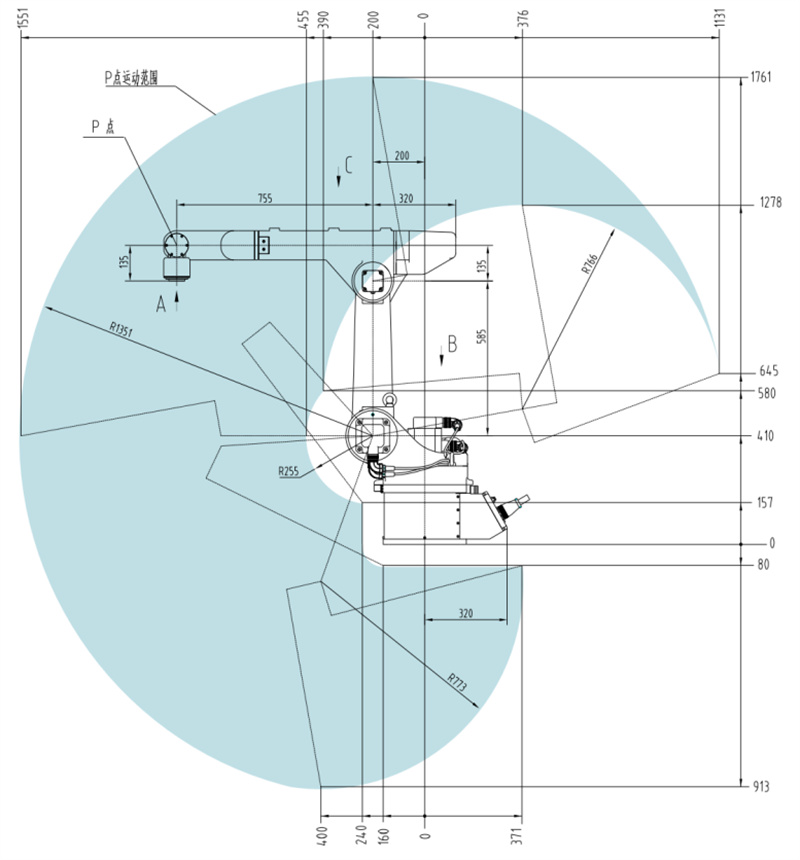

“PNC is a software tool that was developed by Rockwell and I developed this tool about 25 years ago, and it will turn your PLC into a CNC controller. It will allow you to run a CNC program, an M code, G code program, right out of your PLC, and it will allow you to do the CNC applications right out of the PLC,” said Miller. Painting Robot Arm

Miller added that PNC has many perks that have exceptionally simplified and changed operations given its versatility. “The real beauty of a CNC controller is the flexibility, that CNC in general will allow you to run a variety of a lot of different parts — that’s what CNC does. So the ability to run a PLC in that mode is very beneficial.” he said

In addition to that, Miller also said that it not only promotes ease-of use, but further helps in lessening any challenges that might arise with more difficult or complex systems. “PLC is a very simple device, very easy to maintain, very user-friendly, so that’s a big advantage to the system. You can utilize the benefits of PLC and it will allow you to run a complicated CNC type of system,” added Miller.

Flynn, in accordance with Miller, said the control system greatly assisted his team in solving a complex problem for a customer. He explained that while initially complicated, his understanding of it came very quickly and easily. “It was a little convoluted at first, but we were easily able to take the existing servo drives and motors and controls and everything, and add the PNC package and make it very user-friendly, and ended up being a great success and the customer was very happy with it,” said Flynn.

Miller said the value of this system is the importance of how easy it is to use. Its navigability reduces chances of issues forming because troubleshooting is just as effortless, and he stated there’s no special hardware, firmware, nor software included.

Flynn said the overall functionality of PNC, and “adding G codes or M codes is impressive.”

Follow us on social media for the latest updates in B2B!

MarketScale creates and publishes industry-leading B2B content for industries ranging from Education to Retail, and Hospitality to Healthcare delivering engaging and educational live shows, online learning courses, virtual events and more.

Control Robot Sign up to receive the latest in industry-leading B2B content.